Many machines on which vibration switches are installed

experience certain non-destructive high-level vibrations during their

normal starting and running conditions. Robertshaw has developed a

"supervisory" (monitoring) system for use with Model 365 and 366 electric

Vibraswitch units. This supervisory instrument is called a MONITOR and/or

CONTROL UNIT. The Vibraswitch instruments used with this monitor or

control unit must have electrical reset coils.

To better understand the reasons for starting and

monitoring time delays, reference to Figure 6 shows typical vibration

levels on an operating machine with respect to time. Since some of these

vibration levels are higher than the set-point adjustment on the

Vibraswitch, the monitor control unit must contain certain supervisory

logic that will sort out the false short term disturbances so that alarm

and shut-down will not occur; but if a valid (long term) high level

vibration occurs, then alarm and shut-down must be initiated

Refer to Figure 6, periods (1) through (5).

(1) STARTING TIME DELAY — The vibration level did

exceed the Vibraswitch set-point. However, the control unit "locked out"

the Vibraswitch control contacts during the time delay periods as set on

the control unit. Without the starting time delay, the machine would not

have reached its normal operating speed because the Vibraswitch would

have shut it down prematurely.

(2) NORMAL VIBRATION LEVEL — After the machine

reaches its normal operating speed and the vibration level has assumed a

level below the set-point value, the Vibraswitch and the control unit are

passive. With the average machine in good mechanical condition. the

"normal" vibration level will dominate for an indefinite period.

(3) TRANSIENT SHOCKS - Monitoring time delay is used to

"sort our" these short duration high level vibrations which are non

destruction to the machine but would cause shut-down. These short duration

disturbances are caused by such things as sudden load changes on pipeline

pumps, by sudden closing of diverting valves, check valves or by air

pockets in liquid lines, pump cavitation, etc. Each time the set-point had

been exceeded by the transient disturbance the monitoring time delay

circuit is energized and the Vibraswitch is reset and a second "sample" is

made to determine if the Vibraswitch requires resetting again. The total

monitoring time is adjustable; usually from 2 to 5 seconds are the most

popular time settings. If the Vibraswitch set-point is not exceeded, then

the control unit remains passive.

(4) DESTRUCTIVE VIBRATION — The sampling and

monitoring circuit is energized immediately on high level vibration

(above the set-point on the Vibraswitch) and approximately five "samples"

will be made during the monitor time period. If all five samples indicate

the vibration level was above the set-point. then the monitor circuitry

will actuate the alarm or shutdown contacts.

(5) ALARM OR SHUTDOWN — The control unit contacts are

locked into the alarm or shutdown conditions until the operator resets the

system.

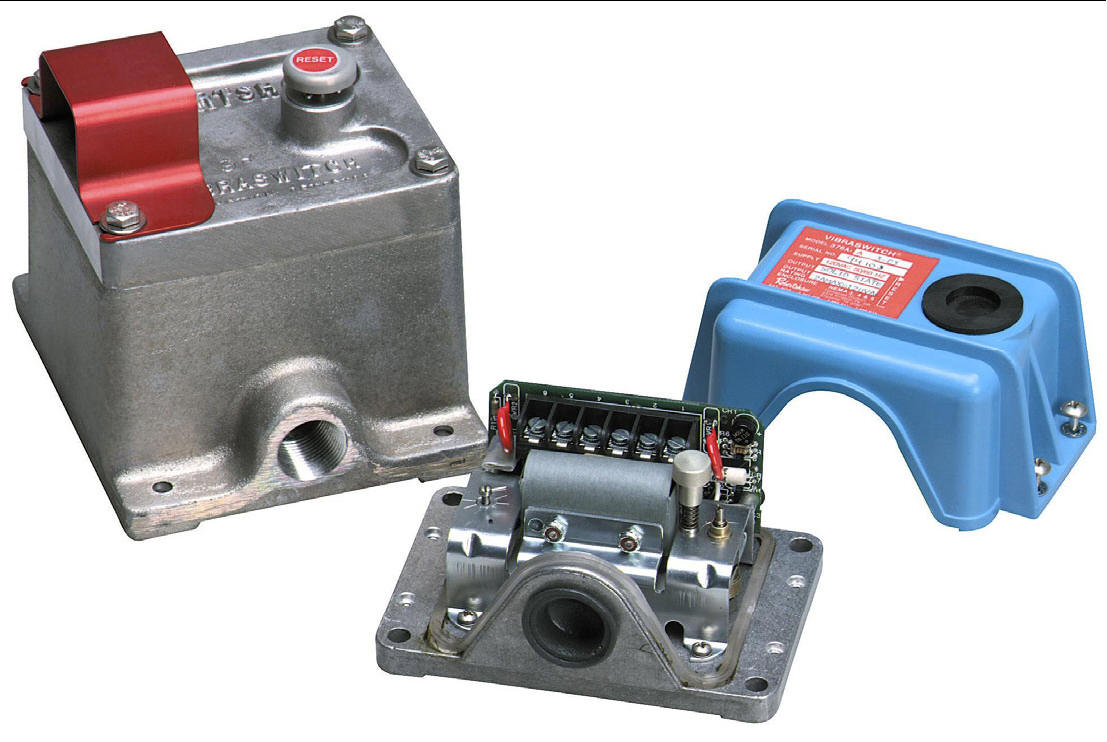

MODEL 375A AND 376

The Model 375A and 376A

vibration detectors are identical in

outside dimensions and appearance to the famous Model 365 and 366.

However, these instruments include built-in solid state electronic

circuitry for start and/or monitoring time delay functions for prevention

of false shutdowns due to transient vibrations.

The Model 375A and 376A

vibration detectors are identical in

outside dimensions and appearance to the famous Model 365 and 366.

However, these instruments include built-in solid state electronic

circuitry for start and/or monitoring time delay functions for prevention

of false shutdowns due to transient vibrations.

The 375A is FM approved for Class I, Division 1, Groups

C & D; Class II, Division 1, Groups E, F & G; and Class III, Div. 1

hazardous locations.

The Electronic Vibraswitch offers complete vibration

protection in a single compact package. It is available at low initial

cost and saves both time and labor in its installation. The instrument is

available in Start Only Time Delay, Monitor Only Time Delay or with both

Start and Monitor Time Delay. For the Start Delay Only version the output

switching is SPDT rated 5 amps at 120 or 240 VAC. The output switching for

the Monitor Only and Start and Monitor versions is a solid state optically

isolated TRIAC which will supply up to 2 amperes at 120 VAC 50/60 Hz. to

an external load.

HOW THE UNIT FUNCTIONS

Start Delay Only models hold the Vibraswitch armature in

its reset position for a preset starting time after application of supply

voltage to the instrument. This prevents the Vibraswitch from tripping out

during machine startup. Fixed timing periods of 15, 30, 60 or 90 seconds

are available. After the time period, the Vibraswitch functions as normal

with shutdown or alarm functions provided by utilizing the SPOT switch

contacts in the Vibraswitch.

Monitor Delay Only models prevent nuisance shutdowns due

to tripping out of the Vibraswitch during high level short term transient

vibration conditions by automatically resetting the Vibraswitch. Under

continuing high vibration, the Vibraswitch trips, is immediately reset,

trips out again, it resets again, etc. This "sampling" process continues

until the time delay period has elapsed, after which the unit remains

"tripped" out. An AC output by means of an optically isolated solid state

TRIAC switch can be used for either alarm or shutdown. The solid state

switching mode can be changed by means of a solderable link to the

equivalent of an NO (for alarm) or NC (for shutdown) electrical contact.

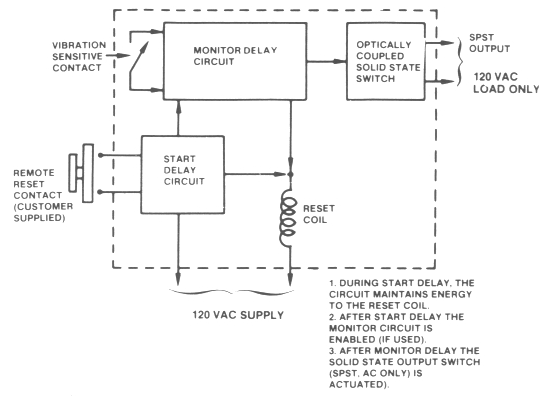

Figure

7

Block Diagram: Start and Monitor Electronic Vibraswitch

Refer to Figure 7 showing the

basic block diagram of the Electronic Vibraswitch for the functional

operation of the unit. For dimensional data, refer to page 6 on Models

365/366.

INSTALLATION AND APPLICATIONS

The Vibraswitch must be mounted on a flat surface so

that all four corners are in rigid contact with the mounting surface. If

the machine has irregular surfaces, a heavy steel mounting plate can be

used, but it must be rigidly attached to the machine. Typically, one-half

inch steel plate is satisfactory and it should be made as small as is

consistent with the size of the Vibraswitch base to reduce resonance

effects. The vibration sensitive axis of the Vibraswitch is perpendicular

to its base; therefore it must be mounted in the correct plane to detect

the vibratory motion for which protection is desired.

A preferable location is in line with rotating main

shafts and as near bearings as is possible. Typical machines requiring

protection are pumps (both reciprocating and centrifugal), fans, blowers,

compressors, gear boxes, mills, turbines, etc.

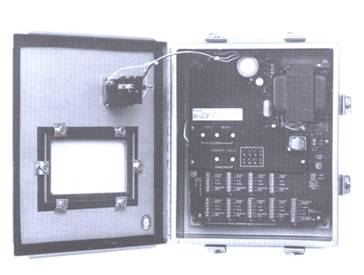

Model 563A

The Model 563A is a microprocessor based monitor and

control unit. The solid-state electronic system will "sort out" false

signals received by the Vibraswitch so that alarm and/or shutdown will not

result from false transient disturbances. It has field adjustable Start

Delay from 0 to 999 seconds and Monitor Delay of 0 to 99 seconds.

Eight LED indicators, viewable through the window on the

instrument door, are provided for visual indication to determine which

Vibraswitch detected the excessive vibration and triggered the alarm

and/or shutdown.

Optional enclosures are weather-proof NEMA 4 or

explosion-proof for Class I. Division 1, Groups C & D hazardous locations.

The unit is designed for use with one to eight Vibraswitch Models 365 or

366. Power supply options are 120 VAC, 50/60 Hz.; 240 VAC, 50/60 Hz.; 24

VDC or 48 VDC.

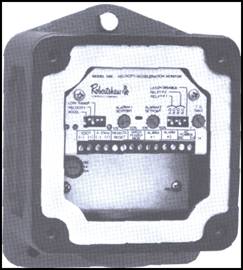

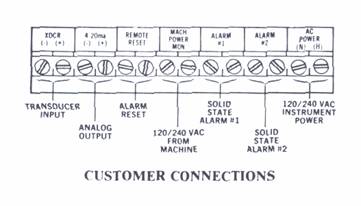

MODEL 566

The Robertshaw Model 566 Vibration Monitor is a solid

state instrument that encompasses a variety of functions all in one unit.

Vibration can be monitored in either velocity or acceleration. The

standard ranges are 0 to 1.5 inches/second or 0 to 3 inches/second when

sensing velocity and 0 to 5 G's or 0 to 10 G's when sensing acceleration.

A 4-20 maDC output is standard.

The Model 566 includes two solid state Triacs (2 amp @

120/240 VAC) which can be operated in a N.O. or N.C. configuration. Alarms

are capable of being latched or non-latched (ON-OFF). A time delay

function is also a standard feature and is adjustable from 0.5 to 15

seconds. LED setpoint indicators are provided to indicate the alarm

condition. Options include P/S (120 or 240 VAC) and remote sensor. The

remote sensor can be located up to 1,000 feet away using only a standard

ungrounded pair of twisted wire.

The Model 566 enclosure is designed to be weatherproof

and explosion-proof. The enclosure rating is NEMA 4 and Class I, Division

1, Group C and D; Class II, Division 1, Group E, F and G. Housing for the

remote mounted transducer has the same rating plus Class I, Group B.

Note that on the remote sensor unit the connection from

the Model 566 to the remote sensor need only be two ungrounded wires.

PRINCIPLE OF OPERATION

The Model 566 employs totally solid state circuitry.

Velocity or acceleration sensing mode of operation is field selectable

without loss of accuracy. The unit is factory calibrated in all ranges.

Two alarm setpoints are standard plus use of a built-in 4-20 maDC output.

A machine power monitor input, such as 120 or 240 VAC is

provided to enable the monitor delay and analog output circuitry when the

monitored unit is turned on. The time delay period can be set in the field

up to 15 seconds.

The indicators (LED) will illuminate when the setpoints

are reached. They are electrically connected in the circuit prior to the

time delay to allow for field calibration of the alarm setpoints without

shutting down the machine being monitored.

Alarm # 1 - Operates with adjustable time delay (0.5-15

Sec.). When the vibration signal continues to exceed the setpoint for as

long as the time delay setting, the alarm actuates.

Alarm #2 - Actuates when vibration signal exceeds

setpoint. No time delay function available.

Latch Disable - Disables alarm latches. When on, alarms

reset automatically when vibration level returns to normal.

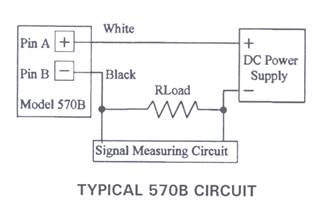

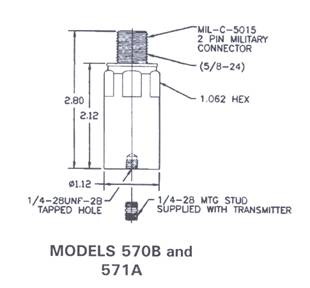

MODEL

570B AND MODEL 571A

LOOP POWERED STUD MOUNTED VIBRATION TRANSMITTERS

The model 570B is a 10-30 vdc loop powered vibration

transmitter which provides a 4-20 mADC output proportionate to vibration.

The transmitter is available with a measurement range of either 0-5 g,

0-10 g or 0-20 g peak acceleration, or 0-0.5 IPS, 0-1 IPS or 0-2 IPS peak

velocity; and the frequency range is 2 Hz to 2 KHz. This rugged compact

unit provides continuous monitoring of machine vibration for trending,

alarm and/or shutdown when used with a PLC, computer, DCS, data logger or

current relays. The enclosure is 316L stainless steel, NEMA 4X

(hermetically sealed), and meets IP68.

Installation is simple and no calibration is required. A

1/4-28 stud is provided for mounting. The unit has a 2 pin connector and

mates with a standard MIL-C-5015 2 socket connector with a splash proof

connection. Optional cable assemblies are available in lengths of 16, 32,

64 and 112 feet.

The model 571A is a 14-30 vdc intrinsically safe version of

the model 570B. It is CSA Certified for use in the USA and Canada for

Class I, Division 1, Groups A, B, C & D; T3C; when connected to an

approved barrier. For non-incendive environments a safety barrier is not

required. It is also ATEX Certified EEx is IIC T3 for use in Europe when

connected to an approved barrier.

Features and Benefits:

Two wire loop powered (10 – 30 VDC)

4 – 20 mADC output (isolated)

Compact design, 1.12” diameter, 2.80” height

Corrosion resistant (316L Stainless Steel)

NEMA 4X, IP68, hermetically sealed enclosure

ESD and EMI protection

Overload protection

Reverse wiring protection

Available for either acceleration or velocity measurement

CE Certified

No Trim Pots required