WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov

ABB FPD570 Compact Wedge Flowmeter (flow meter)

ABB has been supplying DP devices from their very beginnings in the 19th century and have unrivalled experience in the field, incorporating the expertise of Kent, Taylor and Bush Beach. The Taylor wedge ( Kent Taylor is now ABB ) has developed a strong reputation for handling difficult flow metering applications.

ABB can offer a complete range of DP Flowmeters - not only the primary elements but also the secondary transmitter and the recording/control/indication instrumentation that you need.

Having no moving parts and no tendency to wear or foul, the ABB WedgeMaster wedge flow meters, based on the segmented wedge principle, are the logical choice when there are concerns over meter performance and longevity.

In addition the FPD570 WedgeMaster can meter flow at very low Reynolds Numbers and with short upstream straight pipe lengths.

The wedge flow meter is the best choice for metering for high viscous flows and slurries.

The FPD570 WedgeMaster is a wedge design based flow meter designed to greatly simplify specification, installation and commissioning. The assembled one piece flow meter features the following:

- Wedge meter element with a choice of pipe sizes from DN25 to DN150 (1 to 6 in.)

- Integral 3-valve instrument manifold (optional 5-valve manifold available)

- Optional integral temperature element for corrected volume / mass calculations

- Integral DP or multivariable transmitter, factory-fitted to the manifold

- Fully leak-tested and configured

- Compact flowmeter with integral transmitter, manifold and temperature element

- - for volumetric- or mass-flow metering available for pipe sizes 1 to 6 in.

- problems caused by impulse piping are eliminated by mounting the transmitter and manifold directly on to the meter

- complete with manifold and ABB DP or Multivariable transmitter

- Corrosion and erosion resistant

- - V-shaped restriction eliminates damage from the secondary phase

- no critical surface dimensions to wear and affect performance

- durable with excellent long term stability

Minimum requirements for straight pipe

Flow is conditioned within the meter body without compromising on performance. Only 5 pipe diameters upstream and 3 diameters downstream is all that is needed for specified performance, enabling the meter to be used in difficult pipe work configurations.

Calibrated for optimum accuracy

All meters are water-calibrated to verify actual meter coefficient, providing a metering accuracy of up to 0.5 % of reading when used within calibrated range.

Factory acceptance report

All meters are supplied with report detailing results of critical inspection checks, plus certification data

Benefits

WedgeMaster avoids many of the difficulties involved in the sizing, selection, procurement, installation and commissioning of conventional DP flowmeter installations.

With all the major components in one assembly, WedgeMaster eliminates the problems of sourcing multiple components. It provides large savings in cost and time due to the simplicity of purchasing, design and installation.

The Integral transmitter and manifold with compact tapping connections eliminates the need to run and connect impulse piping and offers: guaranteed accuracy of positioning and installation of the tapping points reduces the possibility of impulse line blockage

The assembly is pressure-tested in the factory, giving the user confidence that the connections between the tapping points and the transmitter are completely free of leaks.Every flowmeter is flow calibrated, ensuring the performance of the complete flowmeter, not just the flow element.

The 'Plugged Impulse Line Detection' (PILD) feature generates a warning via HART communication if either or both of the impulse lines become fully or partially obstructed (for example, by foreign material or ice). The meter can also be configured to drive the analog output signal to the 'Alarm current'

The New 'through-the-glass' (TTG) keypad technology enables configuration without the need to remove the transmitter covers, even in hazardous areas.

Factory configuration saves the user time during commissioning and ensures that the flowmeter output span truly matches that of the application flowrate.

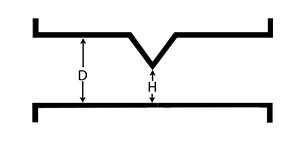

WedgeMaster utilizes a V-shaped restriction to produce a differential

pressure that has a square root relationship to volumetric flow.

WedgeMaster utilizes a V-shaped restriction to produce a differential

pressure that has a square root relationship to volumetric flow.

WedgeMaster is available with 4 standard wedge ratios to cover a wide range of application flow rates. The wedge ratio is defined as H/D where H is the wedge opening height and D is the nominal pipe diameter. The restriction is V-shaped at an optimum angle to give the best possible characteristics when measuring viscous fluids. The element is suitable for applications where the pipe Reynolds number is as low as 500 (well into the laminar flow zone) and as high as several million