|

ROBERTSHAW VIBRATION SWITCH UNITS

MODEL

365A

FM Approved, CSA Certified

The Model 365

Vibraswitch is an acceleration sensitive instrument that measures the

total peak vibratory shock (destruction forces) present at the point of

measurement. The instrument's explosion proof housing meets Class I,

Division 1, Groups C and D, and Class II, Division 1, Groups E, F and G

hazardous area classifications. It is FM approved and CSA certified. The

instrument provides electrical switch contact closures for on-off control

of alarms and shut-down of machines. Both SPDT and DPDT contact

arrangements are available.

The

set-point is provided with a dial calibrated in 0.1 G divisions. The

instrument has a range of 0 to 4.5 G in a frequency range of 0 to 300 Hz.

The set-point adjustment resolution is 1 G per turn. The Vibraswitch can

be supplied with an electrical reset coil for remote resetting; it is

available for voltages of 24, 48, 120VDC or 120 VAC. A

The

Model 365 Vibraswitch is an acceleration sensitive instrument that

measures the total peak vibratory shock (destruction forces) present at

the point of measurement. The instrument's explosion proof housing meets

Class I, Division 1, Groups C and D, and Class II, Division 1, Groups E, F

and G hazardous area classifications. It is FM approved and CSA certified.

The instrument provides electrical switch contact closures for on-off

control of alarms and shut-down of machines. Both SPDT and DPDT contact

arrangements are available.

The

set-point is provided with a dial calibrated in 0.1 G divisions. The

instrument has a range of 0 to 4.5 G in a frequency range of 0 to 300 Hz.

The set-point adjustment resolution is 1 G per turn. The Vibraswitch can

be supplied with an electrical reset coil for remote resetting; it is

available for voltages of 24, 48, 120VDC or 120 VAC. A

MODEL

366

CSA Certified

The Model 366

Vibraswitch is an acceleration sensitive instrument that measures the

total peak vibratory shock (destruction forces) present at the point of

measurement. The instrument is housed in a general purpose,

weather-resistant enclosure meeting NEMA type 4 specs. The cover is ABS

high impact thermoplastic material and the base is aluminum 360 (Cu Free).

The Model 366 is CSA certified. It provides electrical switch contact

closures for on-off control of alarm and / or shut-down of machines. It is

available with SPDT or DPDT contact arrangements.

The

set-point is provided with a dial calibrated in 0.1 G divisions. The

instrument has a range of 0 to 4.5 G in a frequency range of 0 to 300 Hz.

The set-point adjustment resolution is 1 G per turn. The Vibraswitch can

be supplied with an electrical reset coil for remote resetting; it is

available for voltages of 24, 48, 120 VDC or 120VAC. A manual reset button

is supplied as standard equipment on all units.

MODEL EURO 366 VIBRATION SWITCH

The Model EURO 366 Vibration Switch is primarily intended for indoor and outdoor hazardous and nonhazardous areas in those

countries requiring ATEX and CE certifications. The EURO 366 employs the

same time proven switch design found in Robertshaw's family of vibration

switches.

intended for indoor and outdoor hazardous and nonhazardous areas in those

countries requiring ATEX and CE certifications. The EURO 366 employs the

same time proven switch design found in Robertshaw's family of vibration

switches.

The Model EURO 366

Vibration Switch is a vibration sensitive device that protects rotating

and reciprocating machinery from extensive damage resulting from

mechanical malfunction. When the vibration level of a Vibration Switch

protected machine exceeds normal by a preselected amount, the normally

open contacts of an internal switch close and the normally closed contacts

open. This can be used to actuate either an audible warning system or a

shutdown circuit before costly damage occurs Failing bearings, broken

blades and similar

malfunctions cause

increased imbalance or high frequency vibration detectable with the

Vibration Switch. It is designed for

maintenance-free

service in permanent installations.

The Vibration

Switch is an acceleration sensitive instrument that measures the total

acceleratory shock present on the machine. Acceleration is a vibration

characteristic of prime importance in cases of

mechanical failure

on reciprocating or rotating machinery. Acceleration is directly related

to the shock

forces (impact)

acting on a machine - thus the Vibration Switch offers a valid measurement

of the

destructive forces

acting on the machine.

Accelerator

measurements made by the Vibration Switch are the summation of all

of the

individual

accelerations giving a total destructive force acting on the

machine - the result is positive

protection.

MODEL

368 PNEUMATIC VIBRATION SWITCH

VIBRATION PROTECTION USING PNEUMATIC POWER

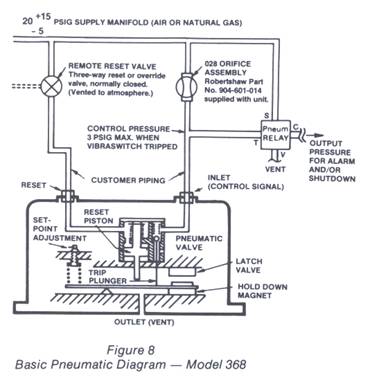

The

Robertshaw Model 368 Vibraswitch is a pneumatically powered detector for

use on machines where electrical power is not available. This instrument

is particularly well suited to installation in hazardous (explosive)

areas (even in extreme hazard such as hydrogen atmospheres) since only

compressed air is required for its alarm and/or control operation. It does

not require explosion-proof housings. The instrument is also well suited

for applications at pipeline compressor stations and skid-mounted

compressors since it will operate on either natural gas or compressed air.

The

Model 368 is identical to the Model 365/366 Vibraswitch in its principle

of operation as described in this bulletin: refer to Figure 4 for its

basic operation.

OPERATION OF THE PNEUMATIC VIBRASWITCH

When

the instrument is subjected to vibration perpendicular to the base, the

resultant vibratory intertial force, aided by the adjusting spring, pulls

the armature away from the hold-down magnet. Magnitude of this inertial

force is proportional to the mass of the armature and the acceleration

component of the vibratory motion. F = MA where force (F) is equal to mass

(M) times acceleration (A). Refer to Figure 8 for the basic pneumatic

diagram of the Model 368 Vibraswitch.

When

the peak acceleration exceeds the set-point level, the armature breaks

away from the stop pin. moving the trip plunger upward to open the

pneumatic valve, which is normally closed maintaining a 20 psig pressure:

on opening, the inlet (controlled) line pressure drops to 3 psig or lower.

The

pneumatic valve vents into the sealed cover and out the exhaust (vent)

port. The decrease in control pressure is used to actuate a pneumatic

relay which will initiate alarm or shutdown of the malfunctioning

equipment.

When

the instrument is subjected to vibration perpendicular to the base, the

resultant vibratory intertial force, aided by the adjusting spring, pulls

the armature away from the hold-down magnet. Magnitude of this inertial

force is proportional to the mass of the armature and the acceleration

component of the vibratory motion. F = MA where force (F) is equal to mass

(M) times acceleration (A). Refer to Figure 8 for the basic pneumatic

diagram of the Model 368 Vibraswitch.

When

the peak acceleration exceeds the set-point level, the armature breaks

away from the stop pin. moving the trip plunger upward to open the

pneumatic valve, which is normally closed maintaining a 20 psig pressure:

on opening, the inlet (controlled) line pressure drops to 3 psig or lower.

The

pneumatic valve vents into the sealed cover and out the exhaust (vent)

port. The decrease in control pressure is used to actuate a pneumatic

relay which will initiate alarm or shutdown of the malfunctioning

equipment.

|