Vibration Overview

VIBRATION SWITCH SENSORS

How Vibration Switches

Work and Protect You Equipment from Destructive Vibration

The Robertshaw

vibration switch offers many features not usually available in competitive

vibration instruments. Some of these features are:

1.

Models

are available with ELECTRIC or PNEUMATIC switching action.

2.

Units

respond to the DESTRUCTIVE forces, not displacement.

3.

No

MAINTENANCE required. no moving parts to wear insures long life.

4.

CONTINUOUS PROTECTION for operating machines.

There are more than 125,000 Robertshaw vibration switches in use all

over the world making these instruments by far the most widely used

vibration detection system available.

HOW

THE VIBRATION SWITCH OFFERS POSITIVE

PROTECTION

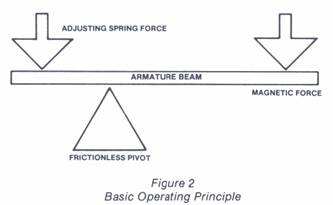

Figure 2 is a line

diagram of the basic operating principle. The detector mechanism consists

of an armature (pendulous mass)

suspended on a flexure pivoted beam. It is restrained from motion in

its normal (reset) condition by means of a permanent hold-down magnet

acting through a small air gap. A compression spring provides an

adjustable force opposing the magnetic force and this

serves as the adjustable SET-POINT

which is calibrated directly in G's

(acceleration units). The armature acts

as a beam: it is forced in one direction by the adjustable spring,

and in the other direction it is balanced by the magnetic force as

indicated in Figure 2.

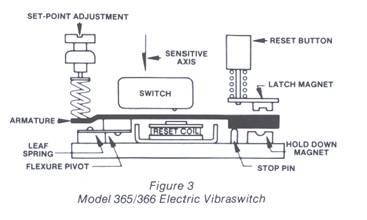

The armature is

constrained to a single direction of movement (sensitive axis) by using a

relatively wide flexure pivot assembly

composed of two overlapping blocks and a leaf spring loaded in one

direction so as to hold the blocks together as shown in Figure 3.

When the entire assembly is subjected to vibration perpendicular to

the base. the peak acceleration (A) times the effective mass (M) of

the armature produces an inertial force

(F = MA). This force is aided by the spring, which tends to pull

the armature away from the hold-down magnet and the stop pin, When the

peak acceleration exceeds a

pre-selected set-point level, the armature leaves the stop

pin. and moves up to the latch magnet. which holds it in the "alarm"

(excess vibration) position until it is reset.

Motion of the armature

actuates a snap-action switch, either an electrical or pneumatic type,

which signals that the set-point has been exceeded. The vibration switch is an accurate and dependable but

simple mechanical accelerometer with "on-off" control output.

To the basic design

the following refinements are added:

1.

Temperature Compensation.

The effect of

temperature in the mechanism is negligible as the elastic modulus of the

adjustment spring and the magnetic flux through the air gaps both decrease

slightly with increasing temperature;

these two effects are, therefore. compensating.

2.

Set-Point Adjustment.

This screw allows

setting the force on the spring-loaded end of the armature to compensate

for "normal" machine vibration plus the desired "safety" factor of the

particular machine involved. The dials

are calibrated directly in G units through a range of 0 to 4.5 G's.

3.

Electric or Pneumatic Reset.

An

electromagnet attracts the armature when energized with a voltage, or a

pneumatically actuated plunger forces

the armature back to the "reset" position. It is used for remote

resetting after actuation, and for "locking out" the vibration switch

during abnormal machine vibrations that may occur during start-up or

transient shock conditions.

4.

Manual Reset Button.

This permits

manual resetting of the vibration switch after actuation (tripping).

Figure 4 shows the basic operating parts of the Model 368 vibration switch

for operation on pneumatic power. It is basically the same unit as the

electric type except for the pneumatic valve assembly.

SIMPLICITY OF INSTALLATION

AND ADJUSTMENT

The vibration

sensitive axis of the vibration switch is in a direction

perpendicular to its mounting base.

Therefore it must be mounted on

the machine in a plane that will detect the vibratory motion for which

protection is desired. Normally bent

shafts, unbalances on the rotating mass of the shaft, worn

bearings, and other mechanical abnormalities are best detected near the

bearing housings and at right angles to the rotating shaft. Do not mount

the vibration switch perpendicular to the ends of rotating shafts unless

an end-play or end-thrust measurement of the shaft is desired.

The base must be

rigidly mounted on a flat surface so that all four

corners of the base are contacting the

surface. If a mounting plate is

attached to the machine, it must be very rugged in order to prevent

introduction of mechanical (plate) resonances into the vibration switch.

Adjustment

The set-point is initially adjusted to its maximum G value by turning

it fully counterclockwise. If the machine is operating normally (with-out

excessive vibration), slowly turn the set-point clockwise until the

switch actuates. Then advance the set-point counterclockwise five

divisions on the graduated dial (0.5

G). Adjustment is then

complete.

See Also:

Understanding the Physical

Characteristics of Vibration

Typical Vibration

Switch Installations