Vibration Overview

TYPICAL VIBRATION SWITCH

INSTALLATIONS

TYPICAL INSTALLATION ON A MACHINE

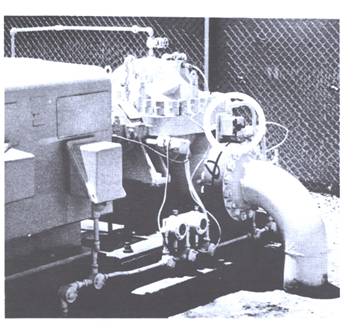

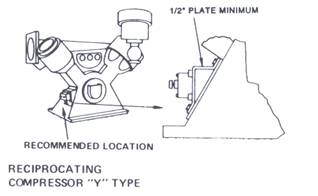

The

photograph illustrates an installation of a Robertshaw vibration switch on a

reciprocating compressor. The sensing unit (detector) is placed on the

machine in a location that will permit the unit to be responsive to

excessive and damaging vibration. In this application the detector is

mounted on a heavy bracket which in turn is rigidly bolted to a heavy

inspection cover located opposite the main crank shaft and bearings of the

compressor. In this location the vibration switch will detect any excessive

vibration due to bearing wear or loose parts associated with either of the

two compressor pistons and their connecting rods which are driven by the

main crank shaft.

and damaging vibration. In this application the detector is

mounted on a heavy bracket which in turn is rigidly bolted to a heavy

inspection cover located opposite the main crank shaft and bearings of the

compressor. In this location the vibration switch will detect any excessive

vibration due to bearing wear or loose parts associated with either of the

two compressor pistons and their connecting rods which are driven by the

main crank shaft.

Typically, the detecting element is placed as close to the bearing

assemblies, crank shafts, driven gears and other rotating or reciprocating

parts as possible in order to be responsive the malfunctions of these

parts

APPLICATIONS

Nearly all rotating or reciprocation machines are

candidates for vibration measuring and control or alarm instrumentation.

The following list of machines are typical:

The types of failures these machines typically suffer most

often are

TYPICAL VIBRATION

SWITCH INSTALLATIONS

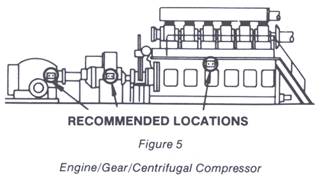

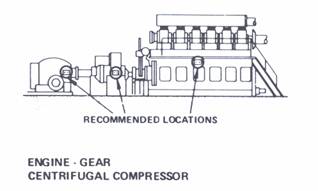

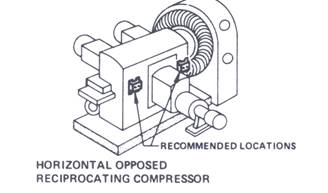

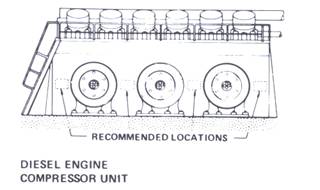

The line

drawing shown in Figure 5 indicates typical mounting locations for the

vibration switch detectors on a multiple unit machine

consisting of a diesel engine driving into a gear box which in turn is

driving a centrifugal compressor. A

vibration switch detector is mounted on each of the major units as

near the main drive bearings as

possible on both the centrifugal compressor and the gear box. The

diesel engine is protected by only a single vibration switch located at a

mid-point on the engine frame; better protection would be afforded with

additional detectors mounted on the engine at the ends of the engine near

the drive bearings.

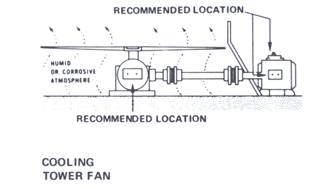

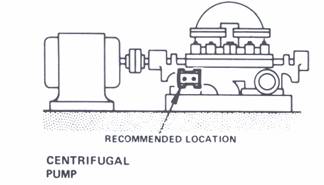

Typical installation

of an explosion-proof vibration switch on a motor driven centrifugal

pumping unit. The circled area indicates the

mounting location of the vibration

switch on the centrifugal pump used in a petrochemical pipeline

installation at one of the pumping stations.

The drive motor is a 600 hp, 3500 rpm unit driving directly a high

pressure centrifugal pump operating at approximately 450 psig

pressure.

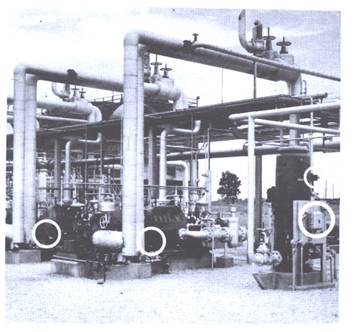

Multiple vibration

switch installations at a liquified petroleum gas production facility.

The unit circled at the extreme right of the photo-graph

shows an explosion proof vibration switch and associated control unit mounted

on the motor drive unit of a vertically driven pump. The vibration

switch is mounted approximately at the motor mid-point so that it will be

responsive to any excessive vibration of either the

motor or the vertical pump. The motor

drive speed is 4500 rpm. The

control unit is mounted on a free standing vertical panel along with

Start, Stop and Reset switches required by the system.

The circled areas to

the center and left of the photograph shows the installation of additional

vibration switch detectors on motor driven centrifugal pumps at this LPG

processing facility.

RECOMMENDED INSTALLATION LOCATIONS

See Also:

Understanding the Physical

Characteristics of Vibration

Vibration Switch Sensors